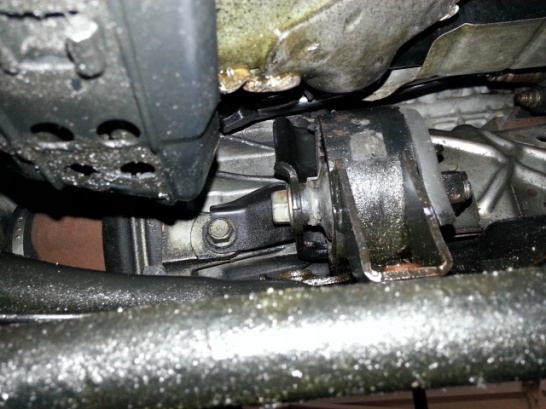

DIY of PWR steering Rack N pinion project. Some suggest dropping the subframe partially, some suggest remove subframe completely! Both way I have experience PROs and Cons! Details info and Pics will be posted for update!

Tools for DIY:

10, 12, 14, 17, 19mm sockets, wrench, and all size extension

1/4", 3/8" ,1/2" ratchet and 1/2" toque wrench (up to 200 ft lbs)

1/2" impact gun (remcomment) and 3/8" air ratchet (optional)

17mm & 19mm impact socket

Specialty wrench (17mm flare nut wrench or crowfoot socket)

22mm deep socket ( power

steering pressure line switch)

steering pressure line switch)

measure tape and whtie out for reference marking

1/2 qt power steering fluid or Dexron ATF

Loosen the power steering pressure line to drain the fluid with 22mm deep socket!

Tools for DIY:

10, 12, 14, 17, 19mm sockets, wrench, and all size extension

1/4", 3/8" ,1/2" ratchet and 1/2" toque wrench (up to 200 ft lbs)

1/2" impact gun (remcomment) and 3/8" air ratchet (optional)

17mm & 19mm impact socket

Specialty wrench (17mm flare nut wrench or crowfoot socket)

22mm deep socket ( power

measure tape and whtie out for reference marking

1/2 qt power steering fluid or Dexron ATF

Loosen the power steering pressure line to drain the fluid with 22mm deep socket!

Attachments

-

95.4 KB Views: 48

-

86.5 KB Views: 51

Last edited: